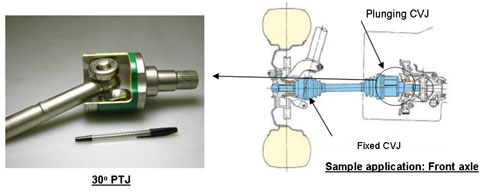

September 29th 2014 tripod jointstep. It is ideal for medium working angles and its low plunge resistance aids good nvh characteristics.

Constant Velocity Joints Ntn Bearing

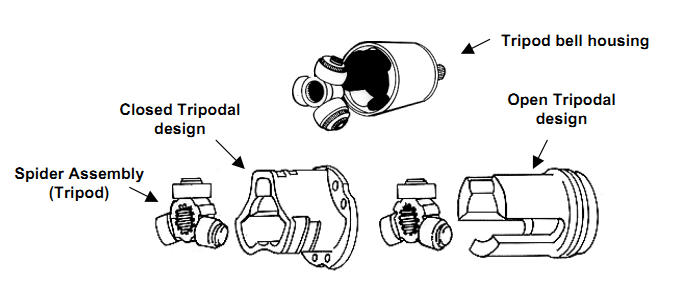

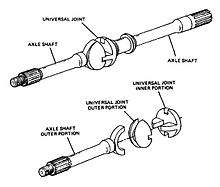

Tripod cv joint design. The standard tripod joint gi is suitable for the inboard gearbox joint of a constant velocity sideshaft for most vehicles. In this research an instrumented advanced cv joint friction tester was developed to measure the internal friction behavior of cv joints using actual tripod type joint assemblies. Tripod plunging gi joint. This joint is not a true constant velocity joint since the medium plane always lies perpendicular to the axis of the drive shaft. Constant velocity joints also known as homokinetic or cv joints allow a drive shaft to transmit power through a variable angle at constant rotational speed without an appreciable increase in friction or playthey are mainly used in front wheel drive vehicles. Tripot joint tripod ball cv joint hartford technologies bearing specialists collaborate with prominent automotive and off road vehicle tier 1 companies to design and manufacture production volumes of tripot joint components.

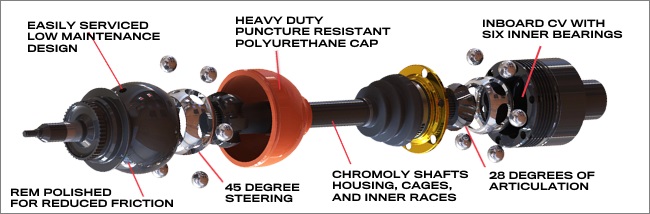

Download cv joint guide series 30 934 930 cv boots. Tripod housings fsae items are only available direct through rcv performance at msrp. The setup is capable of measuring key performance parameters such as friction and wear under different realistic operating conditions of oscillatory speeds and cv joint installation angles. Rzeppa undercut free tripod anti shudder tripod cross groove double offset. The computer aided design cad files and all associated content posted to this website are created. Modern rear wheel drive cars with independent rear suspension typically use cv joints at the ends of the rear axle halfshafts and.

The vl3 cv joint currently being used on the side shaft of independent rear suspensions on the bmw 5 series and 7 series luxury vehicles is said to deliver 27 more torque with no increase in packaging size. 2a and 2b illustrate weak portions in the tripod joint which should be considered in the joint design in order to provide a tripod constant velocity joint having a desirable strength in terms of a torsional strength and a durability or torsional fatigue in particularin the tripod joint design the shortest or minimum diameter sd of shaft 5 is typically considered to be the weakest. In addition to the properties of the standard tripod joint the low plunging resistance and low axial forces of the aar joint delivers additional nvh noise vibration hardness refinement making it appropriate for high working angles. State of the art cae cv joint design. It has a maximum articulation angle of 23 degrees and has a plunge length of 50mm. Silicone neoprene high temperature thermoplastic.

50 degrees outboard 28 degrees inboard. A clever new constant velocity cv joint is smaller and lighter freeing up room for space constrained automotive designers. September 29th 2014. Tripod plunging aar joint angular adjusted roller.